|

|

|

|

AUSCHWITZ:

Technique

and Operation

of

the Gas Chambers © | |

|

| |

|

Back |

|

Contents |

Page 136 |

|

Home

Page |

Forward |

|

| |

| Document G2a |

|

Document G2b

[PMO File BW 11/1, page

3] |

| |

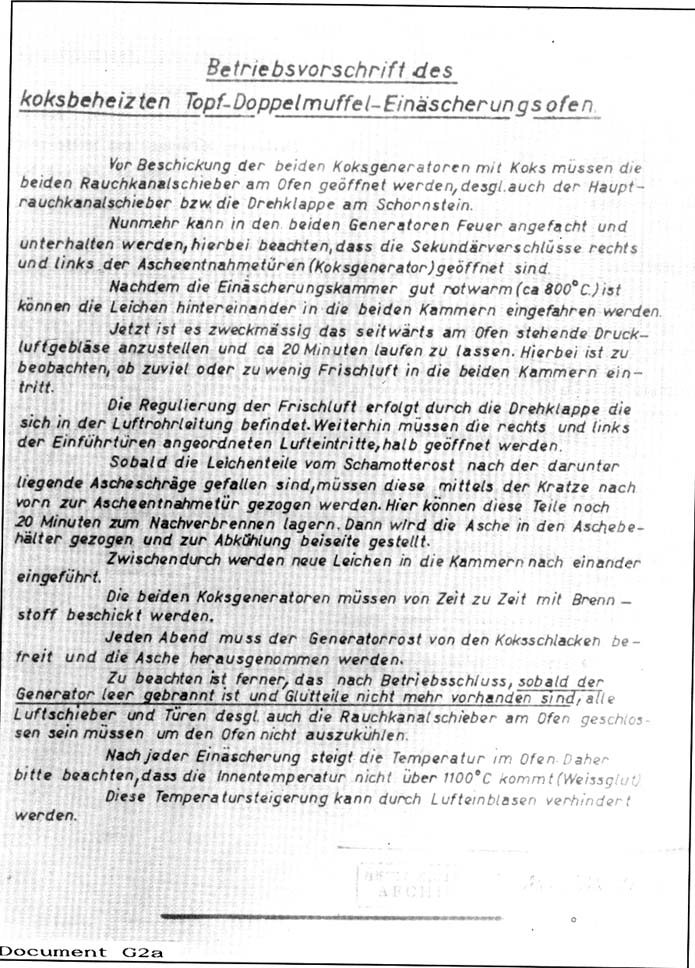

OPERATING INSTRUCTIONS FOR

COKE-FIRED TOPF

DOUBLE-MUFFLE INCINERATION

FURNACE |

| |

Before charging the two hearths with coke, the two furnace

dampers and the main rotary damper in the chimney must be open.

The fire can now be lit and maintained, being sure to open

both secondary openings to the right and left of the cinder removal

doors (of the coke furnace).

Once the cremation chamber

(muffle) has been brought to a good red heat (approximately 800°C),

the corpses can be introduced one after the other in the cremation

chambers.

Now the pulsed air blower situated to the side of

the furnace should be switched on and run for about 20 minutes,

ensuring that the two cremation chambers do not receive too much or

too little fresh air.

Regulation of the fresh air is by

means of a rotary valve in the air duct. In addition, the air

intakes, to the right and left of the chamber doors, should be half

open.

As soon as the remains of the corpses have fallen from

the chamotte grid to the ash collection channel below, they should

be pulled forward towards the ash removal door, using the scraper.

Here they can be left for a further 20 minutes to be fully consumed,

then the ashes should be placed in the container and set aside to

cool.

In the meantime, further corpses can be introduced one

after the other into the chambers.

The two coke furnaces

must be fed with fuel from time to time.

Every evening, the

furnace fire bars must be cleaned of clinker and the cinders

removed.

In addition, care must be taken that at the end of

operations, as soon as the furnace. having burnt everything. is

empty and no coals remain, that all the air valves, doors and

dampers are closed, so that the furnace does not cool.

After

each incineration, the temperature rises in the furnace. For this

reason, care must be taken that the internal temperature does not

rise above 1100°C (white heat).

This increase in temperature

can be avoided by introducing additional fresh air.

| |

| |

AUSCHWITZ:

Technique

and operation

of the gas chambers

Jean-Claude Pressac

© 1989, The

Beate Klarsfeld Foundation |

|

Back |

Page 136 |

Forward |

|

|